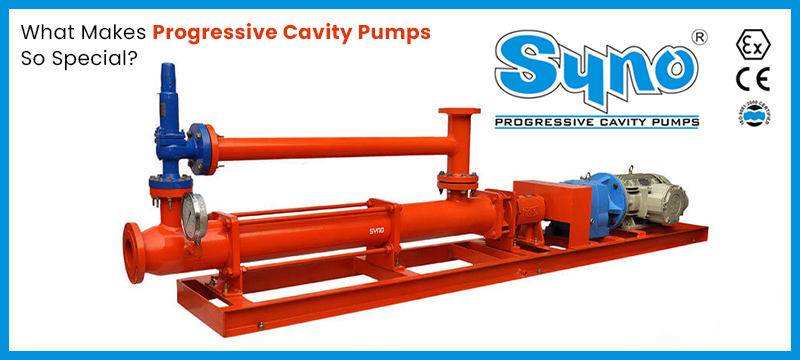

An Overview of Progressive Cavity Pumps (PCPs) in Brief

Industries use stunning pumps to carry out different operations. If you are looking for a perfect pump, progressive cavity pumps play a crucial role in diverse industries. It is the best way to pump food and drink oil, products, viscous chemicals, sewage, and others. You can speak with a reputable professional and acquire a suitable pump to meet pumping requirements. It is available in various industrial designs. Industrialists must look at special types of pumps and their applications.

About progressive displacement pumps:

PC pump also acts as a positive displacement type pump. It is beneficial for many industries to meet application demands. With positive displacement pumps, it is effective in dealing with the highly viscous fluid and extreme pumping application.

It is a versatile pumping solution to carry out a different range of jobs. PC pump is ideal for metering chemicals and pumping abrasive, shear-sensitive, and viscous material. The pump can transfer fluid by progressing fixed discrete cavity via pump. Before using such a pump, one must learn the design, working mechanism, and application.

Design of PC pump:

In the cavity pump, the rotor can be made with steel for smooth, hard surface coating. On the other hand, a stator is made with molded elastomer within a metal tube body. Complex cavities can form in the elastomer core.

- Angled link arm and bearing let the rotor roll across the inner surface of the stator.

- Two designs of stator in the pump are unequal walled and equal walled.

- Unequal walled stator comes with elastomer wall thickness at peak.

- Large-sized solids can move via unequal walled design due to the enhanced ability of the stator to deform under pressure.

- It contains other elements such as a driver, pump body, joint, connecting rod, coupling, packing, bearing, and a lot more.

Working mechanism of cavity pump

The cavity pump serves as the flow creating device that moves fluid at a consistent speed. It comprises of twin helix stator and helical rotor. Fluid can enter the pump via an inlet suction nozzle. The pump draws fluid via a suction inlet that feeds to the elongated casing.

The rotor helix can balance to the stator. If the rotor turns and contacts the stator surface, a series of small cavities initiate to form. The fluid can progress throughout the cavity until it ejects through the discharge outlet. PC pump never let to run dry.

If heat produces by rotor and stator, it causes pump failure. A lot of PC pumps need necessary accessories that safeguard against issues. Additionally, progressive cavity pumps india is completely self-priming. It has a higher pressure per stage than other displacement pumps. It also designs with high suction lift.

Usage of progressive cavity pumps

The main goal of a cavity pump is to pump fluid that is never dealt with by any other industrial pump. It is perfect for diverse usage in the industry.

Easy to dose, pump, and meter chemicals

A cavity pump is a responsible solution to dose, meter, and pump chemicals easily. Cavities within the cavity pump diminish at the end and overlap. There is never flow pulsing other than caused by fluid or pump component compression.

Low-pulsation or smooth pumping makes the PC pump well-suited for metering applications. Cavity pump flow rate can proportional to speed. It is effective to dose high viscous fluids, including additives and chemicals.

Pumping materials comprise an abrasive particle

In other pump designs, fluid travels roughly inside the casing wall at high speed. When pumped materials comprise an abrasive solid, this comb pumps the surface and causes it to wear before its lifespan ends.

- Apart from that, the cavity pump is reliable for taking fluid via a long casing.

- Abrasive particles go equivalent to the internal surface at a slower speed, as disparate to being struck centrifugally at high speed.

- PC pump is abrasion-resistant and works last longer compared to other types of pumps for specific applications.

Pump viscous and heavy fluid

The cavity pump goal is to pump fluid that has a higher viscosity. With the centrifugal pump, the flow rate moves down as fluid viscosity is set up. It is less efficient and enhances energy consumption to keep up.

Cavity pump and other type of pump builds own flow. Moreover, PC pump is more effective as viscosity enhances. It has the same flow rate, and the weight of the pump material never matters. With the help of a high viscosity fluids pump, transfer viscous fluid easily without any hassle.

Pump fluids in applications entail varied flow rate

The cavity pump generates precise flow per revolution. It is easy to maintain pump flow by controlling pump speed. The pump can pair well with varied frequency drives for keeping the flow rate. If you need steady flow, a cavity pump is essential and pumps fluid quickly.