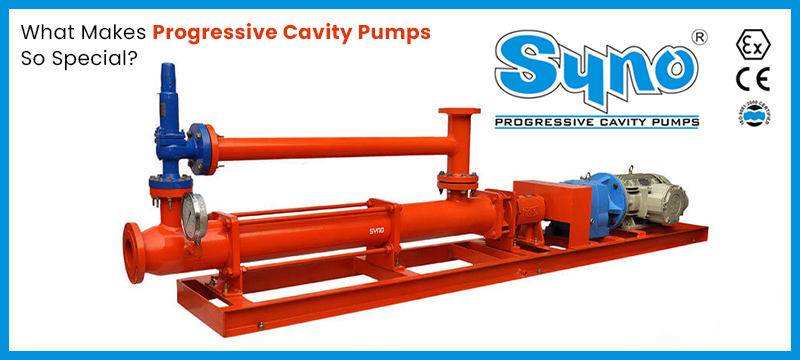

How Dosing Accuracy Is Increased by Progressive Cavity Metering Pumps

In the world of precision fluid handling, achieving accurate dosing is crucial for maintaining product quality, safety, and cost-effectiveness. Progressive cavity metering pumps have emerged as a reliable solution for enhancing dosing accuracy. Here's how they achieve this:

1. Consistent Flow

Progressive cavity pumps create a smooth, pulsation-free flow, ensuring consistent dosing. This is achieved through the unique progressive cavity mechanism, where a helical rotor rotates within a stator, forming cavities that move fluid from the inlet to the outlet.

2. Reduced Human Error

Unlike manual dosing methods, which rely on human operators and are prone to errors, progressive cavity pumps offer automated, precise control. This minimizes the risk of inaccuracies due to miscalculations or misreadings.

3. Handling Viscous Fluids

These pumps are particularly adept at managing fluids with different viscosity levels. The design allows for efficient pumping of high-viscosity fluids without compromising accuracy.

4. Minimal Maintenance

Progressive cavity pumps have fewer moving parts compared to traditional pumps, reducing wear and tear. This results in less frequent maintenance and consistent performance over time.

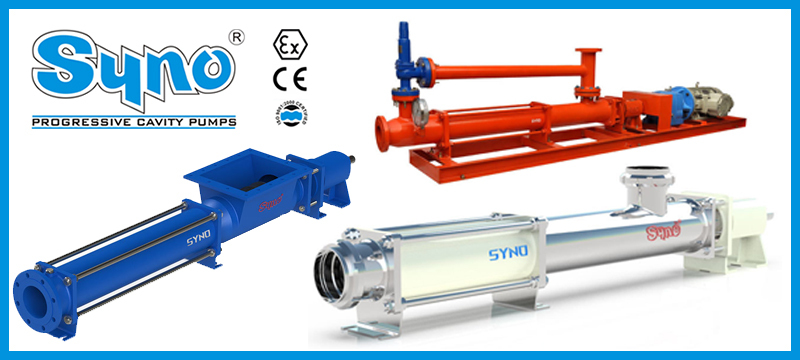

5. Versatility

They are suitable for a wide range of applications, including pharmaceuticals, food and beverage, and wastewater treatment. Their ability to handle abrasive and shear-sensitive fluids makes them versatile and reliable.

Conclusion

Progressive cavity metering pumps offer a leap forward in dosing precision, providing a level of control and reliability that traditional methods struggle to achieve. Their consistent flow, reduced human error, and ability to handle various fluid types make them an invaluable tool in industries where dosing accuracy is paramount.