How to Use Progressive Cavity Screw Pump in Industry and Application

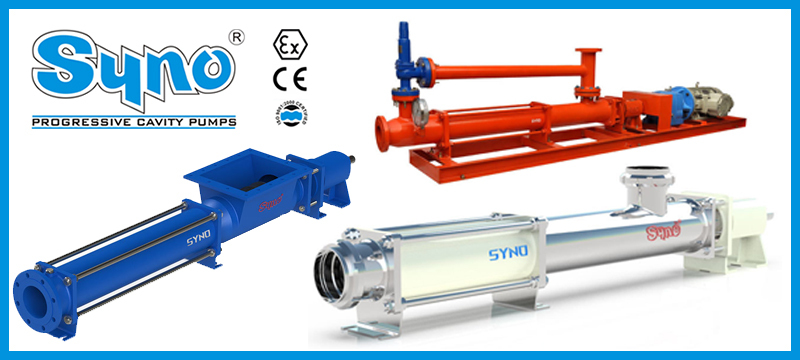

The progressive cavity screw pumps are extremely versatile options, which can be used in various pumping applications. It provides all the advantages of a positive displacement pump and is designed for abrasion resistance in some of the tough pumping applications.

The progressive cavity pump is also targeted as a positive displacement pump. It is different from the centrifugal one. A centrifugal pump is an economic choice when pumping water-like fluids with low viscosity and also when a fixed flow and constant discharge pressure are the primary base of the application.

A proficiently designed centrifugal pump will present you with reliable services for years in simple pumping applications.

When it comes to viscosity:

A progressive cavity pump from the reputed progressive cavity screw pumps manufacturers in India is used when the pumping application is not likely to be suitable for a centrifugal pump.

- One clear example to use a progressive cavity pump is when the liquid has higher viscosity or thickness when compared to water.

- One clear example to use a progressive cavity pump is when the liquid has higher viscosity or thickness when compared to water.

- The opposite will take place when you are using a progressive cavity pump. Here, the volumetric efficiency and mechanical efficiency will go up with the increase in viscosity, lower power and higher flow.

So, it is not hard to state that the progressive cavity pump is ideal for liquids with higher viscosities. On the other hand, this type of pump will have the same flow no matter what the liquid viscosity is. In case you are looking for an application where you need consistent flow, but the liquid viscosity is subject to change, then the progressive cavity pump is your preferred choice.

The art of varying flow:

It is true that the progressive cavity pump from a screw pump manufacturer is ideal when the application is in need of varied flow.

- A progressive cavity pump is known to have precise flow per revolution of the said pump.

- So, it is quite easy to navigate the pump flow by regulating the speed of the progressive cavity pump.

- Some of the modern pump speed controllers like the VFDs are suitable to be used with progressive cavity pumps for varying pump speed and flow control.

- Sometimes, the progressive cavity pump is used for boiler feed applications. Customers use this kind of pump over centrifugal one because of the varying flow needs.

Now for the suction conditions:

There is another good example of when you need to use a progressive cavity pump these days. It is used when the suction conditions are not ideal for the pumping applications.

- A progressive cavity pump needs a lower Net Positive Suction Head or NPSH when compared to a centrifugal pump. It is because the internal velocity is lower.

- On the other hand, it has been proven that the progressive cavity pump can pump when the suction pressure remains low as 28 inches of mercury. A centrifugal pump cannot work under such conditions.

- A progressive cavity pump is designed to easily fill and then pump in various applications, which are hard to cover by the centrifugal pump.

When you need to separate fluids:

The progressive cavity pumps are perfect for applications where the liquid is known to be sheer sensitive because of the lower internal velocity.

- One major example is pumping water and oil mixtures to separation devices.

- Here, the separation device will work way better when the oil droplets are considered larger.

- A progressive cavity pump from a screw pump supplier will not change the oil droplets.

- In the same instance, the centrifugal pump will emulsify the oil and will make the droplets pretty small and will further reduce the separation performance.

For the abrasive solids:

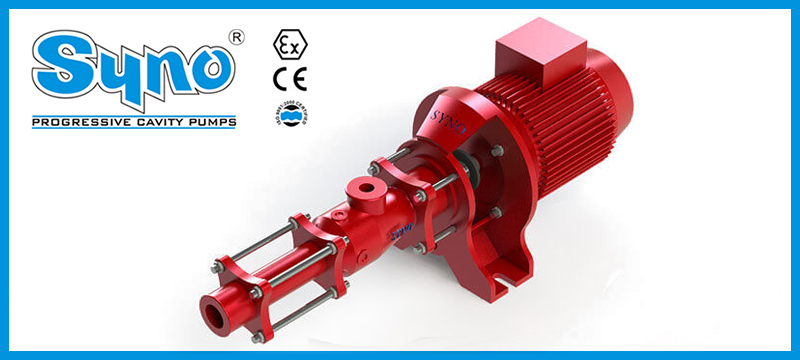

The primary application of the progressive cavity pump is when the liquid holds abrasive solids. Most of the other types of pumps cannot pump solids well or for a very long time because of the all-metal designs and close tolerances.

- A vane or gear pump will wear out when the solids are located in the liquid. The same result would happen to maximum centrifugal pumps and they might end up clogging.

- A progressive cavity pump is well crafted to last longer during such instances when compared to other pumps for abrasive applications.

- The design of the pump with the rotor and stator is always the heart of this design for abrasion resistance.

- On the other hand, the internal velocity of liquid as it travels through the pump is lower than other forms of positive displacement pumps and the rubber stator.

- It is mainly because the flow travels axially through the pump and not around the outside of the casing in a high speed circle like with other designs.

The final say:

From the points mentioned above, it is not hard to state that the progressive cavity pumps from screw pump exporters have higher usability when compared to other pump versions. Checking in with the experienced manufacturer is a must before you invest your money in some types of progressive cavity pumps.