5 Special Conditions Where You Can use Progressive Cavity Pumps

In various industrial applications, pumping the liquid in the systems at the right time in the right volume is the most critical part of the process. The progressive cavity pump is a versatile pumping system that you can use across a huge variety of pumping applications.

The design of this special pump aims to offer maximum resistance against abrasive environments. So, you can enjoy the advantages of having a positive displacement pump once you have got this pump.

The progressive cavity form of the pump is a kind of positive displacement pump. But it is entirely different from the standard centrifugal pumps. But the centrifugal pumps will work well only in simple pumping applications.

Syno-PCP Pumps Private Limited is one of the leading manufacturers of this type of pump.

When to use progressive cavity pumps

Pump manufacturers face a challenging situation when they have to design pumping applications for systems with low NPSH. The requirement is higher in the oil and gas industry as regular pumping of liquid close to vapour pressure is necessary.

If you can choose the right pump technology for the purpose, it's possible to eliminate several complications right from the beginning.

Take a look at the circumstances under which you have to use the progressive cavity screw pump.

1. Systems with higher viscosity

In certain applications, the centrifugal pumps fail to work. For example, when you are dealing with a liquid having higher thickness or viscosity than water, you wl need the progressive cavity pump.

- Centrifugal pumps fail to maintain volumetric accuracy when the liquid’s viscosity increases.

- It will reduce the rate of liquid flow and increase the power consumption level.

- A progressive pump has higher mechanical efficiency.

- The volumetric efficiency is directly proportional to the viscosity of the liquid. So, the flow increases with such a pump.

- The specialized pump also minimizes power consumption.

Thus, when dealing with liquids possessing a high viscosity factor, it is better to use the progressive cavity pump.

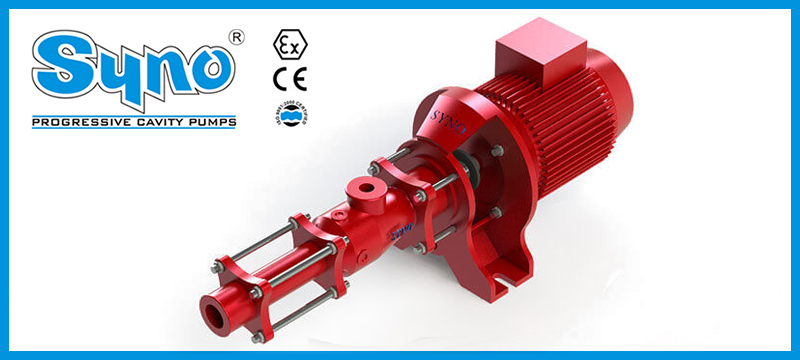

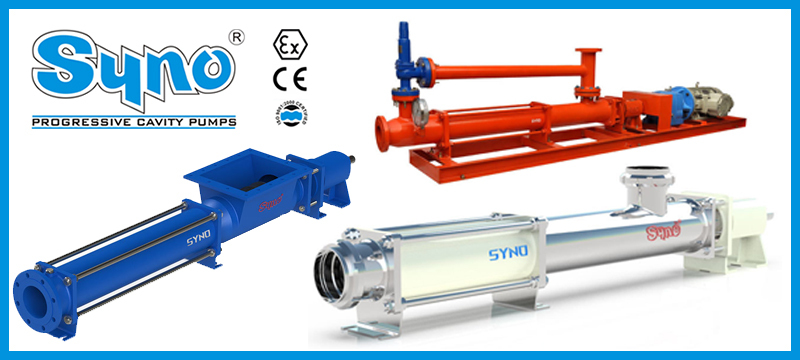

Syno-PCP Pumps Private Limited has earned maximum popularity as the top progressive cavity pump supplier. They have designed more than 20 series of these pumps following over 1400 specifications.

2. Applications with varied flow

The need for these specialized pumps is more when you have got an application that requires variations in flow. A good quality progressive cavity pump will always have a precise flow per revolution.

So, it's quite easy to regulate the flow of the pump with simple adjustments in the pump speed.

- Top-notch manufacturers like Syno will use modern speed controllers like the VFD or variable frequency drive to control the varying pump speeds and flow.

- Their products are also apt for various modern boiler feed applications.

Therefore, you can discuss the needs with the professionals at Syno for developing the right PC pump.

3. Applications with shear-sensitive liquids

The demand for the progressive cavity screw pump is also high these days as it does not influence the liquid separation performance. You need to use these pumps while working with shear-sensitive liquids. Such liquids have a low internal velocity that can suffer from the unwanted influence of the pumps.

For instance, consider using a PC pump for feeding in water and oil mixtures in the separation device. Such a device will work best when the oil droplets are bigger.

Unfortunately, a centrifugal pump will always emulsify the oil and decrease the size of the oil droplets. This will negatively affect the working of the separator.

On the other hand, the PC pump will not influence the size of the oil droplets, leading to better performance of the separator.

Being the dominant progressive cavity pump supplier, the professionals at Syno design unique characteristics for the pumps depending on the nature of the application.

4. Suction conditions

The PC pump is the saviour when you don’t have ideal suction conditions in the pumping application. The Net positive Suction Head or NPSH of the PC pump is much lower than that of the centrifugal pumps.

The reason is the lower internal velocity of the PV pump.

- So, the PC pumps can work even when the suction pressure is alarmingly low, like 28” of mercury.

- These are NPSHr optimized which can deal with values below 0.5m.

Syno-PCP Pumps Private Limited is one of those rare companies where you will find the implementation of all modern technologies. Thus, the company has a wider geographical presence than you expected.

5. Resistant to abrasive solids

If an application involves liquids that possess abrasive solids, the PC pump is the ideal option.

- Any vane pump or gear pump will suffer from quick wear and tear when the liquid contains abrasive solids.

- Centrifugal pumps will clog soon, apart from suffering then damage.

Only the progressive cavity pump can last longer with such abrasive applications. The stator and rotors are resistant to abrasions.

A final word

The expert professionals at team Syno can customize the pumps depending on the features of your applications. As the company has already completed more than 50,000 successful installations all across the world, you can rely on their expertise.

Contact the company at https://synopumps.com/ or email them at info@synopumps.com for more elaborate discussions.