Understanding the Role of Progressive Cavity Pumps in Environmental Sustainability

Progressive cavity pumps (PCPs) are increasingly recognized for their significant role in promoting environmental sustainability across various industries. These positive displacement pumps are designed to handle viscous fluids and solids, making them particularly valuable in applications such as wastewater treatment, sludge transfer, and even in the oil and gas sector. Their unique design and operational efficiency contribute to reduce energy consumption, lower emissions, and improved resource management, all of which are critical components of sustainable practices.

One of the primary advantages of progressive cavity pumps is their ability to maintain a consistent flow rate, regardless of the viscosity of the fluid being pumped. This characteristic is particularly beneficial in wastewater treatment facilities, where the handling of sludge and other high-viscosity materials is common. By efficiently transferring these materials, PCPs help to optimize the treatment process, reducing the time and energy required for processing. This efficiency not only lowers operational costs but also minimizes the environmental impact associated with energy consumption.

In addition to their efficiency, progressive cavity pumps are designed to minimize shear forces on the fluids they handle. This is crucial in applications where the integrity of the material must be preserved, such as in the transfer of biological sludges or delicate solids. By reducing shear, PCPs help maintain the quality of the materials being processed, which is essential for effective treatment and resource recovery. This aspect of their operation aligns with sustainable practices by ensuring that valuable resources are not wasted or degraded during processing.

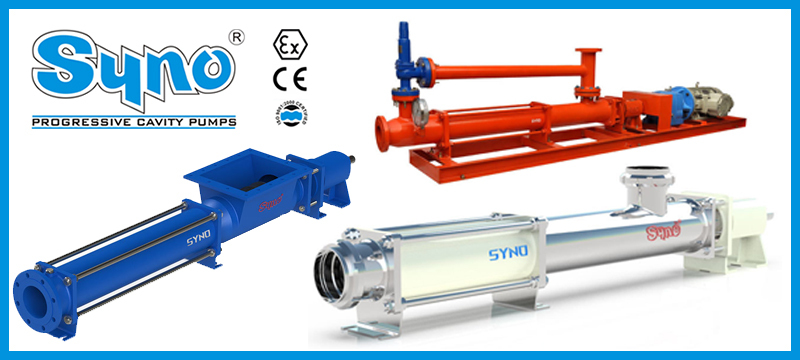

The environmental benefits of progressive cavity pumps extend beyond their operational efficiency. These pumps are often constructed from durable materials that can withstand harsh conditions, leading to longer service life and reduced need for replacements. This durability not only translates to lower maintenance costs but also reduces the environmental footprint associated with manufacturing and disposing of pump components. By investing in high-quality, long-lasting equipment, industries can contribute to sustainability by minimizing waste and resource consumption.

Moreover, progressive cavity pumps are versatile and can be adapted for various applications, including the handling of fibrous materials and abrasive substances. This adaptability allows for their use in diverse sectors, from food processing to chemical manufacturing, where sustainability is becoming increasingly important. By facilitating the efficient transfer of materials in these industries, PCPs help reduce waste and promote the recycling of resources, further supporting environmental sustainability goals.

Advanced Rotor and Stator Design

The heart of a progressive cavity pump is the rotor-stator configuration. The rotor, typically a metallic helical screw, rotates inside an elastomeric stator, forming sealed cavities that progress fluid from the inlet to the outlet.

Another significant aspect of progressive cavity pumps is their role in reducing greenhouse gas emissions. By operating efficiently and requiring less energy to move fluids, these pumps contribute to lower carbon footprints for the facilities that utilize them. In an era where industries are under pressure to reduce their environmental impact, the adoption of energy-efficient technologies like PCPs is a step towards achieving sustainability targets.

Furthermore, the integration of progressive cavity pumps with modern monitoring and control systems enhances their sustainability potential. Advanced technologies, such as IoT (Internet of Things) sensors and predictive maintenance tools, allow for real-time monitoring of pump performance. This capability enables operators to optimize pump operation, detect issues before they escalate, and ensure that the pumps are running at peak efficiency. By leveraging technology, industries can further enhance the sustainability of their operations while minimizing downtime and maintenance costs.

In the context of wastewater treatment, the use of progressive cavity pumps is particularly impactful. These pumps are essential for the effective management of sewage and industrial effluents, which are critical to protecting water resources and public health. By ensuring that wastewater is treated efficiently and effectively, PCPs play a vital role in safeguarding the environment and promoting sustainable water management practices.

Moreover, as industries increasingly focus on circular economy principles, progressive cavity pumps can facilitate the recovery of valuable resources from waste streams. For instance, in biogas production, PCPs can be used to transport organic materials that can be converted into renewable energy.

Progressive cavity pumps are integral to advancing environmental sustainability across various sectors. Their efficiency in handling viscous fluids, durability, and adaptability make them a valuable asset in wastewater treatment and resource recovery applications. By reducing energy consumption, minimizing emissions, and promoting the effective management of materials, PCPs contribute significantly to sustainable practices. As industries continue to seek innovative solutions to meet environmental challenges, the role of progressive cavity pumps will undoubtedly become more prominent in the pursuit of a sustainable future.