How Manufacturers Improve Efficiency in Progressive Cavity Pumps

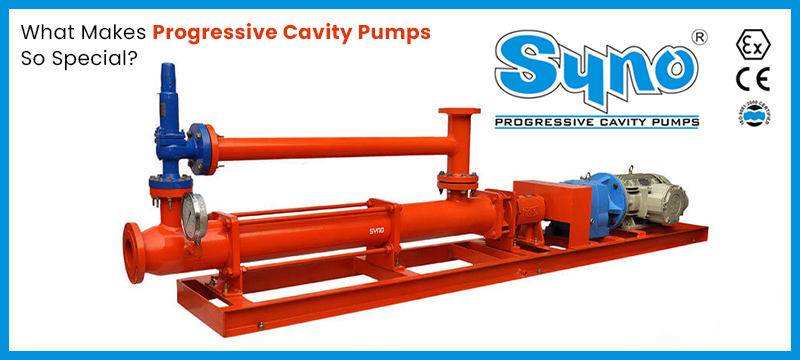

Progressive cavity pumps (PCPs) are essential for handling viscous, abrasive, or shear-sensitive materials across industries like wastewater treatment, food processing, oil and gas, and chemical manufacturing. Known for their precision in fluid handling, PCPs are designed to deliver consistent flow rates even under varying pressure conditions. However, the real challenge for progressive cavity pump manufacturers lies in continuously improving the efficiency of these pumps balancing energy use, longevity, and operational reliability.

Advanced Rotor and Stator Design

The heart of a progressive cavity pump is the rotor-stator configuration. The rotor, typically a metallic helical screw, rotates inside an elastomeric stator, forming sealed cavities that progress fluid from the inlet to the outlet.

How efficiency is improved:

- Precision Engineering : Manufacturers use high-precision CNC machines to create perfectly dimensioned rotors, reducing internal leakage and energy loss.

- Optimized Geometry : The shape and pitch of the rotor and stator are engineered to handle specific viscosities and minimize frictional losses.

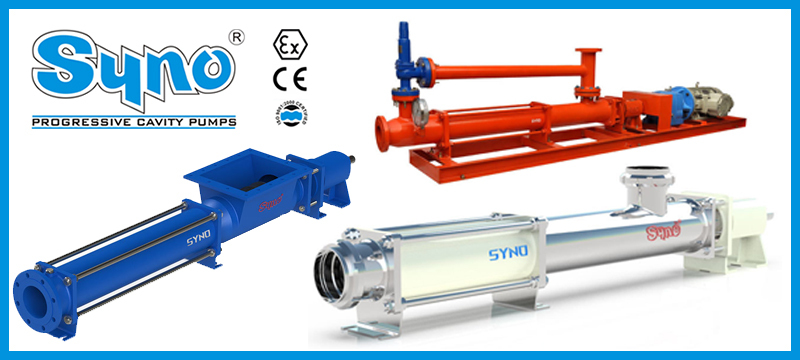

- Custom Material Pairings : Choosing the right rotor (stainless steel, chrome-coated, etc.) and stator (NBR, EPDM, Viton) pairing helps reduce wear and enhances volumetric efficiency.

Use of High-Performance Materials

Wear and tear from abrasive or corrosive media can cause rapid degradation, lowering efficiency. Manufacturers now invest in high-quality materials that offer durability and maintain performance over time.

Efficiency-focused innovations include:

- Abrasion-resistant stator elastomers

- Hard-coated or ceramic-coated rotors

Corrosion-proof housings for chemically aggressive environments

These improvements not only increase pump longevity but also help maintain flow rate consistency, which is vital for dosing and metering applications.

Variable Speed Drive (VSD) Integration

Another crucial innovation enhancing the energy efficiency of PCPs is the integration of variable speed drives (VSDs) or variable frequency drives (VFDs).

Benefits of VSDs:

- Precise Flow Control: Flow rates can be adjusted in real-time based on process demand without compromising pump efficiency.

- Reduced Energy Consumption: Motors can operate at optimal speeds, minimizing power usage during low-load conditions.

- Soft Start/Stop: This reduces mechanical stress on pump components, increasing the lifespan of the system.

Manufacturers often provide built-in VFD systems or compatibility options for seamless integration with existing process automation.

Sealing System Enhancements

Seal failures are a leading cause of pump inefficiency and unplanned downtime. progressive cavity pump manufacturers now focus heavily on seal optimization.

Improvements include:

- Mechanical seal upgrades: Double mechanical seals offer enhanced protection in high-pressure or hazardous applications.

- Seal flushing systems: Reduce heat and prevent clogging, improving overall performance.

- Custom gland packing: For specialized industries such as mining or paper pulp, where aggressive solids are present.

By minimizing leakage and friction around the sealing zone, manufacturers ensure better energy transfer and operational reliability.

Compact and Modular Designs

A shift toward compact, modular PCP designs is another trend aimed at improving efficiency. Modular construction allows for easier maintenance and part replacement, reducing downtime.

Efficiency oriented features:

- Compact footprints reduce space and infrastructure needs.

- Interchangeable components enable quick servicing and customization.

- Lower weight components reduce installation complexity and drive power requirements.

These designs are particularly useful for skid-mounted systems and mobile pumping units.

Improved Manufacturing Process

Behind every efficient pump is a manufacturer committed to innovation in its own production lines. Leading companies employ advanced manufacturing techniques such as:

- Robotic welding for consistent frame strength and accuracy

- Automated testing rigs to verify flow rate and pressure consistency

- Quality management systems (QMS) like ISO 9001 to ensure performance reliability

These process improvements lead to more reliable products with better tolerance, lower energy consumption, and extended service life.

Condition Monitoring & IoT Integration

In the age of Industry 4.0, efficiency doesn’t end at the factory gate. Many progressive cavity pump manufacturers now offer smart monitoring solutions that allow users to track pump performance in real time.

Smart features include:

- Vibration sensors to detect misalignment or imbalance

- Temperature monitoring to identify overheating

- Pressure and flow sensors for dynamic adjustments

- Cloud-based data logging for predictive maintenance

IoT-enabled PCPs ensure that pumps always run at peak efficiency, avoiding overuse, wear, or unnecessary downtime.

Customization for Specific Applications

No two industrial processes are the same. Manufacturers now offer tailored solutions to suit specific operational needs.

Examples include:

- High-pressure designs for oil drilling

- Sanitary-grade pumps for food or pharmaceutical use

- Explosion-proof motors for hazardous environments

Such custom solutions prevent oversizing or underutilization two major culprits behind poor energy efficiency.

Efficiency in progressive cavity pumps is not just about reducing power consumption; it’s about delivering consistent, reliable performance while minimizing operational costs. Leading manufacturers are rising to this challenge by investing in material science, smart technology, and precise engineering. Whether you’re in wastewater management, oil & gas, or food processing, choosing a manufacturer that prioritizes pump efficiency can significantly enhance your operational performance and reduce long-term costs.

If you're in the market for a progressive cavity pump, make sure to evaluate not just the pump specs but the innovations and efficiency strategies the manufacturer brings to the table.