Why Progressive Cavity Pumps Are Essential in Oil & Gas Operations

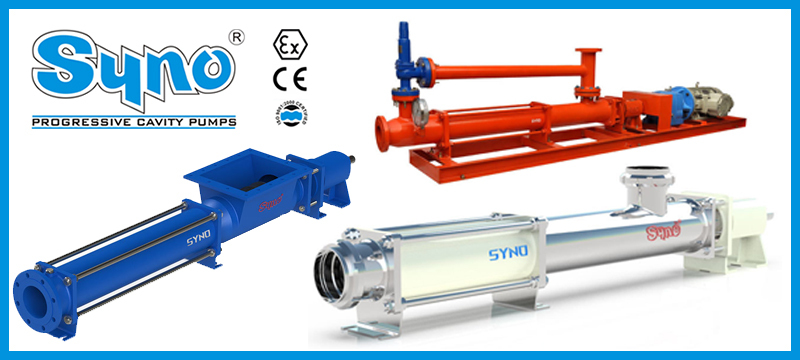

In the dynamic world of oil and gas, efficient and reliable fluid handling systems are not just important — they are critical. Among the many pumping technologies available, Progressive Cavity Pumps (PCP) have carved a unique niche for themselves, thanks to their versatility, consistent flow characteristics, and ability to handle viscous, abrasive, and multiphase fluids with ease.

This blog explores why progressive cavity pumps are essential in oil and gas operations and how they contribute to enhanced productivity, reduced downtime, and optimized extraction and processing.

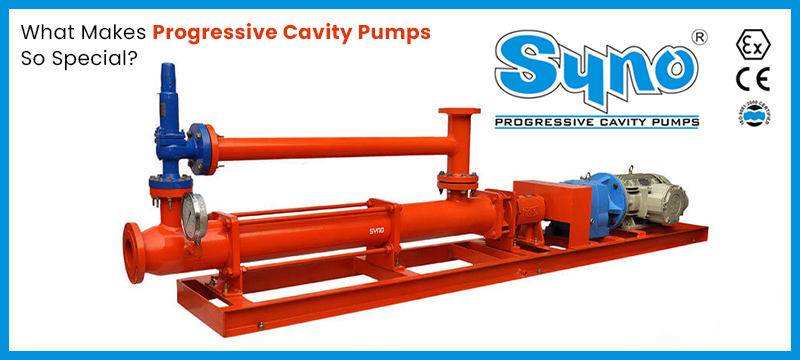

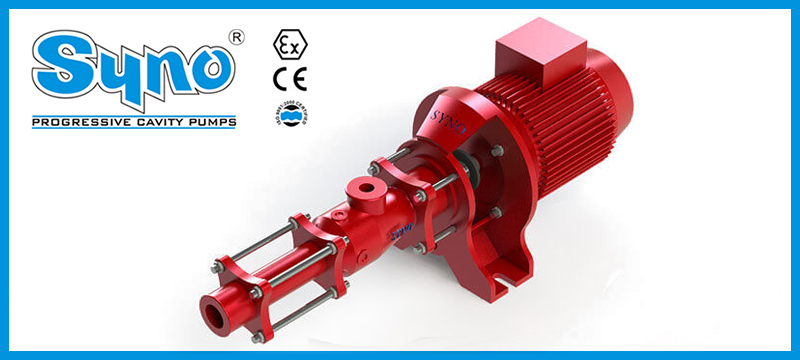

What Is a Progressive Cavity Pump?

A Progressive Cavity Pump is a type of positive displacement pump designed to move fluids through a sequence of cavities formed by a rotor (typically metal) rotating inside a stator (usually made from elastomer). As the rotor turns, cavities open up at the suction side and move the fluid smoothly to the discharge end.

This unique mechanism makes PCPs incredibly efficient for applications where consistency, control, and performance in challenging conditions are required — like in oilfields.

PCPs in the Oil & Gas Industry: Key Roles

Progressive cavity pumps are used across the oil and gas value chain — from upstream production to downstream processing. Here’s how they fit into the ecosystem:

- Enhanced Oil Recovery (EOR) One of the most important uses of PCPs is in artificial lift systems, especially in onshore oil fields. When reservoir pressure drops and natural lift is no longer sufficient, PCPs are deployed to continue extracting oil. They are capable of:

- Handling viscous crude oils

- Pumping heavy oils with sand or water

- Managing low-flow wells The steady, pulse-free flow of a PCP ensures minimal emulsification, making separation of oil, water, and gas more efficient downstream.

- Multiphase Pumping PCPs can transport mixtures of oil, gas, water, and even solids in a single stream — an area where many centrifugal pumps fail. This ability reduces the need for costly phase separation infrastructure and increases efficiency, especially in remote or offshore installations.

- Drilling Mud Transfer PCPs are frequently used to transfer drilling muds, which are high-viscosity fluids containing solids that lubricate and cool the drill bit and carry cuttings to the surface. The abrasive nature of these fluids can wear down traditional pumps, but PCPs handle them with reduced wear and consistent flow.

- Produced Water Management In oil fields, water is often co-produced with hydrocarbons. PCPs can be used to pump this produced water, which may contain oil residues, solids, and chemicals. Their ability to handle contaminated, viscous, and corrosive fluids makes them ideal for this task.

Benefits of Using PCPs in Oil & Gas

So why are PCPs the preferred choice over other pump types in the oil and gas sector? Here are some key reasons:

- Excellent for High-Viscosity and Abrasive Fluids: PCPs excel in handling crude oils that are heavy, waxy, or sand-laden. Their design allows for a gentle pumping action that reduces wear and tear, even in harsh conditions.

- Consistent, Non-Pulsating Flow: The continuous flow of PCPs ensures smoother downstream processing and better control during injection or transfer applications.

- Low Shear and Emulsification: Unlike centrifugal pumps, PCPs apply low shear to the fluids they move. This reduces the risk of forming stable emulsions between oil and water, simplifying separation.

- Energy Efficiency: Due to their high volumetric efficiency and minimal energy losses, PCPs are more energy-efficient than many other pump types, especially over long operational cycles.

- Simple Design with Fewer Moving Parts: PCPs are relatively easy to maintain, have fewer moving components, and can be repaired quickly on-site, reducing downtime and maintenance costs.

- Factors to Consider When Using PCPs in Oilfields: While PCPs offer many advantages, they must be properly selected and installed to perform optimally. Consider:

- Fluid type (viscosity, temperature, abrasiveness)

- Flow rate and pressure requirements

- Depth of the well (for down hole PCPs)

- Elastomer compatibility with the pumped fluid

The Future of PCPs in Oil & Gas

With oil reserves becoming harder to extract and environmental regulations tightening, efficiency, sustainability, and precision are more important than ever. Progressive cavity pumps align perfectly with these evolving demands.

Additionally, the development of smart PCP systems — integrated with sensors and IoT-based monitoring — is making real-time diagnostics, predictive maintenance, and automated performance optimization possible.

As a result, their adoption is expected to increase not just in conventional oilfields, but also in unconventional plays, heavy oil reservoirs, and offshore platforms.

From artificial lift systems to multiphase fluid handling and drilling support, progressive cavity pumps have proven to be a cornerstone technology in oil and gas operations. Their versatility, reliability, and ability to handle tough fluids make them an irreplaceable asset for oilfield engineers and operators.

If your operations involve challenging pumping environments, investing in a well-designed PCP system could be the key to improved performance and profitability.