Advantages and Disadvantages of Progressive Cavity Pumps

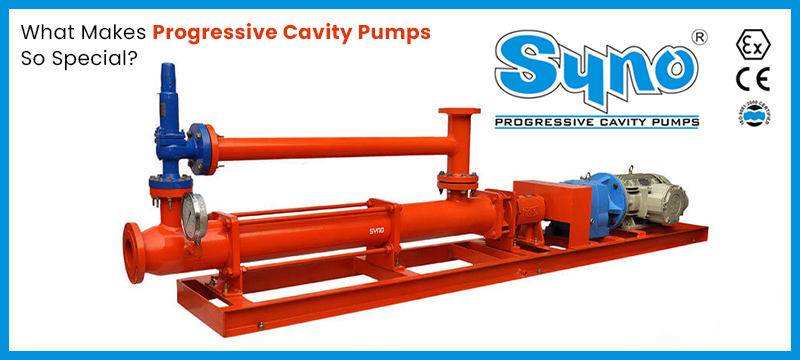

Progressive cavity pumps are basically positive displacement pumps that transfer fluid through a cylindrical chamber with the help of helical screws. These are also known as eccentric screw pumps quite often. Both low as well as high flow rates can be handled by them. Also, they are used to pump viscous, sheer sensitive and abrasive fluids.

In addition to this, these pumps can be more cost-effective in the long run and require less maintenance despite their initial cost. But that's not only what you need to know. There are many advantages and disadvantages that these pumps come with. Before you decide to make a purchase, let's find out about it all.

How Does Progressive Cavity Pump Work?

Before you find out the pros and cons of progressive cavity pumps, let's find out how they work. Basically, the PCP comes with an electric motor which powers the revolving screw.It comes with a stator and has a tube made of plastic or metal. Then a vacuum is created with the rotating screw which draws fluid into the pump which is released at the other end after passing through. The pump's flow rate is determined by the speed of the screw. Depending on the application, progressive cavity pumps can run at extremely high or very low speeds.

Advantages and Disadvantages of Progressive Cavity Pumps

There are many advantages and disadvantages that high-pressure progressive cavity pumps have to offer. To know about them before your purchase, check below to get a clear understanding.

Advantages of Progressive Cavity Pumps

Handling Viscous Liquids

The major advantage of Progressive Cavity Pumps is that they are capable of handling viscous liquids and fluids that may contain suspended solids. Being the best viscous liquid pump, these prevent the chances of damage and wear. It makes them appropriate for use in waste management and mining applications mostly.

Increased Efficiency

Increased efficiency is an advantage of Progressive Cavity Pumps that industries value the most. This is because the pumps are designed with the capability to offer consistent flow rate which also ensures stability and dependability. In industries like oil well production and others - continuous flow is highly demanded.

Assist in Variety of Applications

Another advantage of Progressive Cavity Pumps is that they can assist in a variety of applications suitably. Be it handling the high flow rates or the low ones - these pumps can take care of all.

Efficient in Nature

The progressive cavity pumps take less energy to run due to their relative efficiency when compared to the other types of pumps. As they run in the long term, it can help in decreasing the operating expenses.

Disadvantages of Progressive Cavity Pumps

Higher Costs

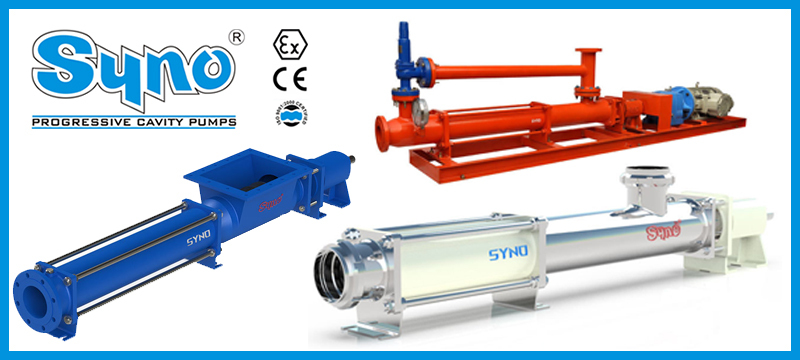

The initial cost of progressive cavity pumps is higher than that of other pump types. However, if you come to us at Syno - PCP Pumps Private Limited, then you may get a chance to grab them affordably.

Maintenance Required

In addition to being expensive comparatively, they are more difficult to fix and require more upkeep than other kinds of pumps.

What are the Applications of These Progressive Cavity Pumps?

There is a wide range of applications of the progressive cavity pump that benefits a number of industries in multiple ways. Some of these industries where they are used are

- Pulp and paper

- Oil and gas

- Food and beverage

- Pharmaceuticals

- Wastewater treatment and many more.

These are frequently employed for the pumping of abrasive, suspended particles as well as viscous liquids. There are hazardous materials like chemicals and radioactive liquids which can also be transferred with the help of the progressive cavity pumps.

Get Pumping Applications for Industries Today

When compared to the other types of pumps available, the progressive cavity pumps offer a number of advantages the potential to handle viscous liquids, handling liquids that have suspended particulates without causing damage and more. They can be used for a number of purposes because they can be pushed at both high as well as low flow rates.

Simply put, the advantages it brings outweigh all the disadvantages. In addition to this, maintenance is quite important if optimal performance is your goal. However, when choosing the best product, you can come to us at Syno - PCP Pumps Private Limited as we are the top food & hygienic pump manufacturer. Over the years, we have done more than 50,000 installations throughout the world which is proof of our huge clientele. On choosing us, you can expect to get quality solutions at affordable rates.