Beginner’s Guide to Dosing Pipes: Their Types, Advantages and Applications

Different industries use different types of pumps for delivering fluids in the applications. Among the various types available, the dosing pumps are the leading ones in use.

The premium quality dosing pumps offer a controllable discharge rate in low volumes for injecting various chemicals and solutions of varied viscosities. These pumps are also termed as metering pumps owing to the accuracy in volumetric discharge rates of the fluids.

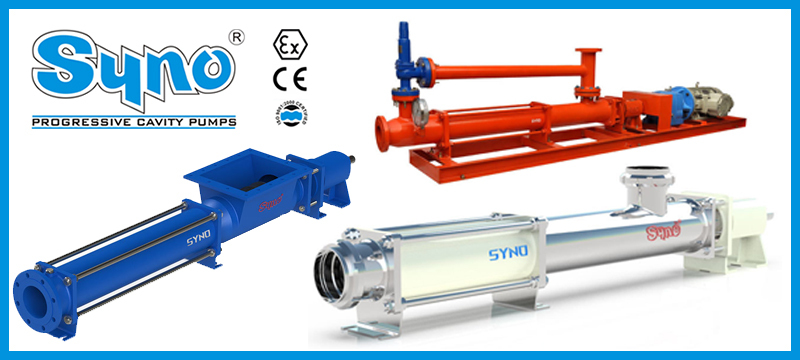

Syno is presently the leading dosing (DC) pumps supplier on the global platform. A brief discussion with the team will help you to understand the basics of these pumps.

Working principle: A brief

The dosing pumps can draw a specified volume of any chemical into its chamber and then inject the same into a tank or a pipe containing water or fluid.

An electric motor or air actuator drives the pump. A controller attached to the electric motor will help to switch on or off the pump and also manage the rate of flow.

Types of dosing pumps:

When you approach a leading dosing pump manufacturer like Cyno for selecting the right kind of dosing pump, it's important to learn about all the types available, before selecting.

When you approach a leading dosing pump manufacturer like Cyno for selecting the right kind of dosing pump, it's important to learn about all the types available, before selecting.

- The dynamic pumps can produce variable flow rates to generate a high flow rate of low-viscosity fluids.

- The positive displacement pumps can maintain a constant rate of flow to produce higher pressure for the high-viscosity fluids.

Now, coming to the types of dosing pumps.

1. Diaphragm pumps

Such pumps show the usage of a flexible diaphragm membrane. The chamber’s volume increases with the expansion of the diaphragm. And this allows the intake of fluid in the pump.

The compression of the diaphragm aids in pushing the liquid out of the pump.

- These are ideal for hazardous liquids owing to the hermetical sealing.

- Appropriate for non-homogeneous liquids

- Zero leakage during operations

- Self-priming

- Easy replacement of damaged parts.

2. Reciprocating pump

This works owing to the repeated forward and backward motion of a piston, diaphragm, or plunger present in the chamber. It helps the fluid to move to the discharge end from the suction side.

3. Plunger or Piston pump

The high-quality dosing pump supplier uses the piston or a plunger to create a vacuum in the pump’s chamber. This helps in drawing the fluid inside. And the forward movement of the piston will compress the fluid to pump it out.

- Self-priming

- Pressure-independent volume discharge

- Production of pulsating flows

- Needs check valve

- Deliver high pressure.

4. Peristaltic pump

This contains flexible plastic or rubber and friction-resistant tubes. The volumetric flow is directly proportional to the rotational speed. Thus, it is ideal as a dosing pump variant.

5. Gear pump

In this variant of DC series dosing pumps, a couple of gears will move clockwise and anti-clockwise for forwarding the fluid.

It's ideal for applications where you need high-pressure output or accurate dosing.

6. Vane pump

It comprises the cylindrical chamber where the vane will rotate to create accurate dosing of high-viscosity liquids.

7. Lobe pumps

Ideal for dosing liquids with higher viscosity in comparison to water. The lobes have a configuration of 2, 3 or 4 and their rotation generates the pumping action.

8. Screw pumps

The function is the same as the lobe and gear pump.

Advantages of dosing pumps

If you are ordering dosing pumps, you should rely on premium dosing pumps manufacturer like Syno. The experts will help to experience the advantages of these pumps.

- You can use these pumps in abrasive and corrosive environments that help to cater to a wide range of industrial uses.

- Ideal for high-pressure, high-temperature applications for injecting chemicals.

- No vibrations or pulsations generated

- User-friendly models to help industrialists start using without complex training procedures

- Ease of installation reduces worries.

- Interchangeable components aid in quick repairs and replacements.

Thus, the DC series dosing pumps from Syno Group can be ideal for different industrial purposes.

Common Applications

Dosing pumps are nowadays used in a variety of industrial segments. You can use the pumps for adding acids or caustic chemicals to the water storage tanks to neutralise the pH.

The metering pipes also serve as chlorine pumps to kill bacteria.

The industries using the pumps include

- Oil and gas

- Farming

- Power plans for feeding the condensate and water

- Paper mills

- Pharmaceutical industries

- pH control in water treatment plants

- breweries

- power generation

- horticulture

- dairy farms

its role is significant in each of the above industries.

Choose the right supplier

But as you can perceive, experiencing the benefits is possible only when you have the right dosing pump supplier. And no one can beat the experience or expertise of the Syno group. The DC series is indeed, a revolutionary model that has served so many industries.

So discuss with the company all your requirements. You can visit them online at https://synopumps.com/ or drop an email at info@synopumps.com. The professionals are highly responsive and will help you through the entire process.