Diagnosing Progressive Cavity Pump Issues

Progressive cavity pumps, also known as positive displacement pumps, are essential in various industries due to their ability to handle viscous fluids and solids. However, like any machinery, they can encounter issues that need troubleshooting. Here’s a simple guide to help you diagnose and fix common problems with progressive cavity pumps.

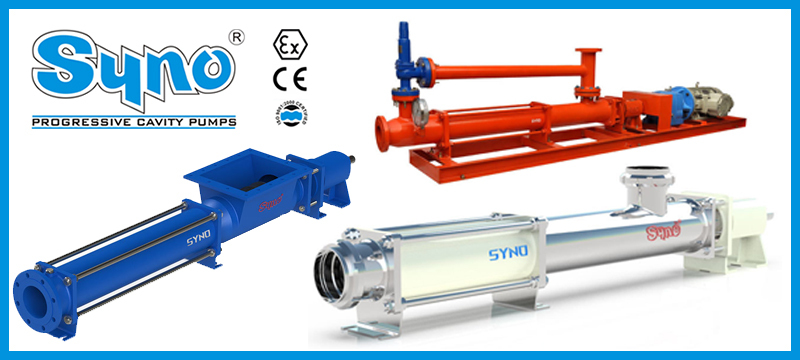

Understanding Progressive Cavity Pumps

A progressive cavity pump consists of a helical rotor inside a stator. As the rotor turns, it creates cavities that move the fluid from the suction side to the discharge side. This design allows for a smooth, non-pulsating flow, making it ideal for handling thick, abrasive, or shear-sensitive fluids.

Common Issues and Solutions

Pump Not Starting

Possible Causes:- Adhesion between the rotor and stator due to inactivity.

- Blockages in the pump.

- Electrical issues such as blown fuses or incorrect wiring.

- Lubricate the rotor and stator with glycerin or inert oil.

- Check and clear any blockages.

- Ensure the power supply matches the pump motor’s requirements and check the wiring.

Reduced Flow or Pressure

Possible Causes:- Wear and tear on the rotor or stator.

- Incorrect pump speed.

- High viscosity of the fluid.

- Inspect and replace worn parts.

- Adjust the pump speed to match the fluid’s properties.

- Verify the fluid’s viscosity is within the pump’s design range.

Excessive Noise or Vibration

Possible Causes:- Misalignment of pump couplings.

- Worn bearings or other mechanical parts.

- Realign the pump couplings.

- Inspect and replace any worn mechanical parts.

Overheating

Possible Causes:- Blockages causing excessive pressure.

- Inadequate cooling.

- Clear any blockages and ensure the pump is not operating beyond its pressure limits.

- Check the cooling system and ensure it is functioning properly.

Leakage

Possible Causes:- Damaged seals or gaskets.

- Incorrect assembly.

- Replace damaged seals or gaskets.

- Ensure all components are assembled correctly and securely.

Preventive Maintenance Tips

- Regular Inspections: Periodically check the pump for signs of wear and tear.

- Proper Lubrication: Make sure to keep all the moving parts well-oiled.

- Correct Installation: Make sure the pump is installed according to the manufacturer’s guidelines to avoid misalignment and other issues.

- Monitor Fluid Properties: Keep an eye on the fluid’s viscosity and temperature to ensure they remain within the pump’s design specifications.

By following these troubleshooting steps and maintenance tips, you can keep your progressive cavity pump running smoothly and efficiently. Remember, regular maintenance is key to preventing issues and prolonging the life of your pump.

Conclusion

Progressive cavity pumps are great for handling thick fluids but can have problems like any machine. To keep them running smoothly, regularly check for problems, fix any issues promptly, and make sure everything is properly set up. This will save you both time and money over time.