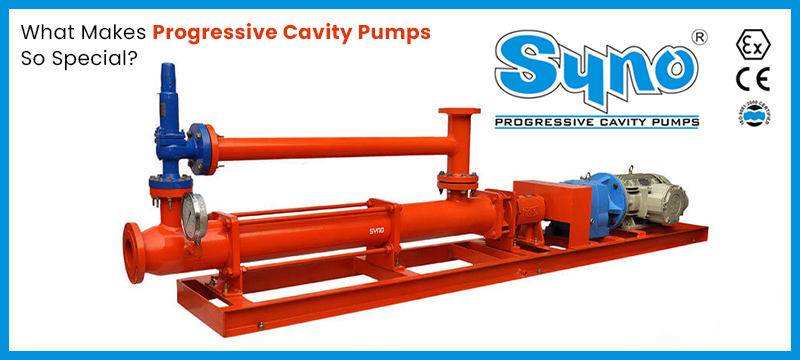

The Growing Demand for Progressive Cavity Pumps in Today's Industries and Their Key Features

Progressive cavity pumps (PCPs) are rapidly gaining traction across various industries due to their efficiency, versatility, and superior handling of challenging fluids. These pumps are known for their ability to transport high-viscosity, abrasive, and shear-sensitive materials with minimal pulsation, making them a preferred choice in sectors such as oil & gas, wastewater treatment, food processing, and chemicals. As industries seek more reliable and high-performance pumping solutions, the demand for PCPs continues to rise.

Why Are Progressive Cavity Pumps in High Demand?

Progressive cavity pumps operate on a positive displacement principle, where fluid is moved through a series of small, fixed cavities. This ensures a steady, controlled flow rate, which is essential for applications requiring precision and consistency.

Key Advantages Driving Demand:

- Superior Handling of Fluids: Works efficiently with thick, abrasive, and shear-sensitive materials.

- Consistent and Pulsation-Free Flow: nsures smooth operations, reducing mechanical stress on systems.

- High Suction and Self-Priming Capability: Ideal for transferring fluids from deep reservoirs.

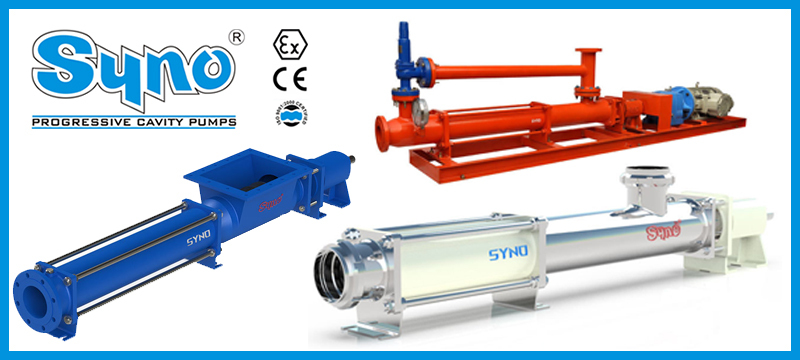

- Customizable for Industry-Specific Applications: Available in various configurations to meet different operational needs.

Industries Driving the Growth of Progressive Cavity Pumps

- 1. Oil & Gas Industry The oil & gas sector extensively uses PCPs for crude oil extraction, enhanced oil recovery, and transporting sand-laden oil. Their ability to handle multiphase fluids efficiently makes them invaluable in upstream and midstream operations.

- Wastewater and Sewage Treatment Municipal and industrial wastewater plants rely on PCPs for sludge transfer, chemical dosing, and grit handling. Their durability and ability to pump solid-laden fluids ensure smooth wastewater processing.

- Food & Beverage Industry PCPs are ideal for handling viscous food products like sauces, dairy products, fruit purees, and dough mixtures. Their hygienic and gentle pumping action preserves texture and quality, making them essential in food processing.

- Chemical and Pharmaceutical Industry Chemical plants use PCPs for precise dosing and transfer of corrosive, hazardous, and viscous chemicals. Their ability to maintain accuracy while handling volatile substances makes them highly valued in chemical and pharmaceutical production.

Feature Demand in Progressive Cavity Pumps

As industries evolve, manufacturers are developing PCPs with advanced features to meet growing demands. Some of the most sought-after features include:

- Energy Efficiency: Modern PCPs are designed to consume less power, reducing operational costs.

- Improved Wear Resistance:Enhanced rotor and stator materials extend pump life and reduce maintenance.

- Customizable Flow Rates: Adjustable configurations allow precise control of fluid transfer.

- Compact and Modular Design: Facilitates easy installation and maintenance.

- Automation and Smart Monitoring: Integration with IoT-enabled systems allows real-time monitoring and predictive maintenance.

Conclusion

The rising demand for progressive cavity pumps is driven by their exceptional performance in handling complex fluids across multiple industries. As businesses focus on efficiency, sustainability, and operational precision, the demand for customized, energy-efficient, and technologically advanced PCPs will continue to grow.

Companies investing in high-quality PCPs can expect improved productivity, reduced downtime, and enhanced cost-effectiveness, making these pumps a smart choice for modern industrial applications.